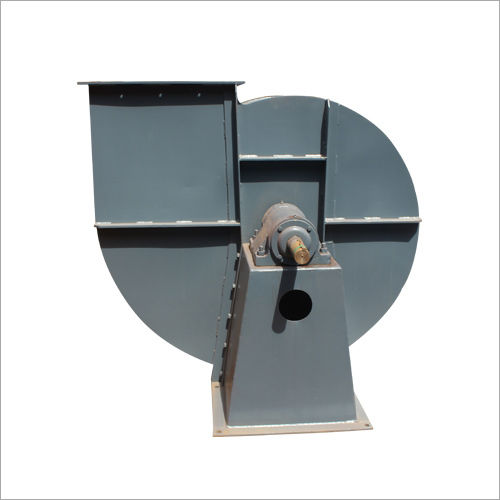

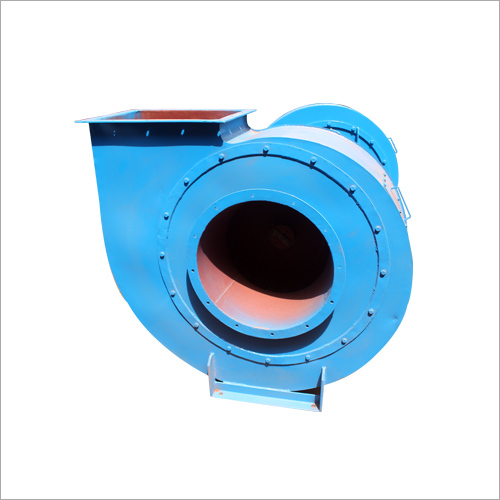

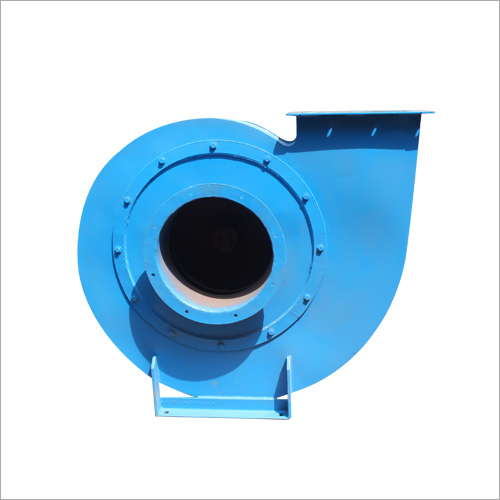

Industrial Exhaust Blowers

Industrial Exhaust Blowers Specification

- Motor Power

- 0.5 HP to 10 HP

- Output Power

- Up to 7.5 kW

- Pressure Range

- 100-200 mm WC

- Flow Rate

- 500-50000 m/hr

- Max Pressure

- 200 mm WC

- Power

- 0.37 kW to 7.5 kW

- Life Span

- 10-12 Years

- Product Type

- Industrial Exhaust Blower

- Material

- Mild Steel / Stainless Steel

- Capacity

- 500-50000 m/hr

- Pressure

- 100-200 mm WC

- Application

- Industrial ventilation, exhaust systems, fume extraction

- Frequency (MHz)

- 50-60 Hz

- Motor Speed

- 1440-2880 RPM

- Noise Level

- Below 85 dB(A)

- Power Source

- Electric

- Voltage

- 220-415 V

- Weight

- Approx. 25-80 kg (Depends on Size)

- Dimension (L*W*H)

- As per Model

- Color

- Grey

- Drive Type

- Belt Drive/Coupling Direct

- Operating Temperature

- -10°C to 80°C

- Enclosure

- Totally Enclosed Fan Cooled (TEFC)

- Impeller Type

- Forward/Backward Curved

- Airflow Direction

- Centrifugal

- Finish

- Powder Coated

- Number of Phases

- Three Phase (Single Phase available on request)

- Mounting Type

- Base Mounted/Flange Mounted

- Fan Blade Material

- Heavy Duty Steel

- Insulation Class

- Class F

Industrial Exhaust Blowers Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Advance (CA), Cheque, Telegraphic Transfer (T/T), Cash in Advance (CID)

- Supply Ability

- 50 Units Per Month

- Delivery Time

- Days

- Main Domestic Market

- All India

About Industrial Exhaust Blowers

Our Industrial Exhaust Blowers are designed to efficiently remove contaminated air, fumes, dust, and excess heat from industrial environments, ensuring a safe and productive workspace. Built with high-performance motors and robust construction, these blowers offer superior airflow and durability, making them ideal for a variety of applications, including factories, warehouses, chemical plants, and manufacturing facilities.

Reliable and Versatile Design

These industrial exhaust blowers are meticulously crafted using heavy-duty steel or stainless steel, offering both forward and backward curved impeller options. The base or flange mounting provides installation flexibility, while powder-coated finishes ensure durability and resistance against harsh industrial conditions.

Efficient Operation and Safety

With a totally enclosed fan cooled (TEFC) motor, Class F insulation, and noise levels below 85 dB(A), these blowers are built to operate efficiently and quietly. Suitable for continuous use in operating temperatures ranging from -10C to 80C, they guarantee stable, long-lasting performance in a variety of industrial settings.

Wide Range of Industrial Applications

Designed to cater to ventilation, exhaust systems, and fume extraction needs, these blowers support capacities from 500 to 50,000 m/hr. They serve as vital components in factories, warehouses, and process plants across Indias diverse industrial landscape.

FAQs of Industrial Exhaust Blowers:

Q: How do I select the right impeller type for my industrial exhaust blower?

A: Choosing between forward or backward curved impellers depends on your airflow and pressure requirements. Forward curved impellers are ideal for higher air volumes at lower pressures, while backward curved impellers suit higher-pressure applications. Assess your systems specifications or consult our engineers for tailored recommendations.Q: What is the advantage of using a Totally Enclosed Fan Cooled (TEFC) motor?

A: A TEFC motor protects the blower from dust, moisture, and other contaminants, enhancing reliability and reducing maintenance. This construction supports continuous operation in industrial environments and ensures longer service life in challenging conditions.Q: Where can these industrial exhaust blowers be installed?

A: Our blowers are suitable for a wide range of applications, including industrial ventilation, fume extraction, and exhaust systems in manufacturing plants, processing units, warehouses, and more. They can be safely base or flange mounted as required by your setup.Q: What is the typical operating temperature range for these blowers?

A: These blowers are designed to perform efficiently in ambient temperatures from -10C up to 80C, making them suitable for most industrial and commercial environments.Q: How do the mounting and drive options impact installation and operation?

A: Base-mounted and flange-mounted designs allow versatile installation, while the choice between belt drive and direct coupling affects maintenance and efficiency. Belt drives enable easy speed adjustments, and direct coupling ensures minimal power loss for higher operational efficiency.Q: What benefits does a powder-coated finish offer for industrial blowers?

A: The powder-coated finish provides enhanced resistance to corrosion and wear, maintaining the blowers appearance and durability even in aggressive industrial atmospheres.Q: Can I get a blower with single-phase power supply?

A: Yes, while our standard blowers are designed for three-phase operation, single-phase variants are available upon request to accommodate different power infrastructures.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Centrifugal Blower Category

High Pressure Direct Drive Centrifugal Blower

Price 18000-100000 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Househol, Packing, Foodprocessing, prinitng, textile, gas analysis, Industrial

Warranty : 1 Year

Motor Speed : 1440 OR 2900 RPM

Color : Industrial Grey

V Belt Drive Centrifugal Blower

Price 30000-150000 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Foodprocessing, gas analysis, Industrial

Warranty : 1 Year

Motor Speed : 800 TO 3500 RPM

Color : Industrial Grey

Industrial Blowers

Price 30000-150000 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Foodprocessing, gas analysis, Industrial

Warranty : 1 Year

Motor Speed : 8003500 RPM

Color : Industrial Grey

Medium Pressure Direct Drive Blower

Price 20000-100000 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Air knives, Soil remediation, Foodprocessing, textile, gas analysis, Other, Industrial, Househol

Warranty : 1 Year

Motor Speed : 14003000 RPM

Color : Industrial Grey

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS